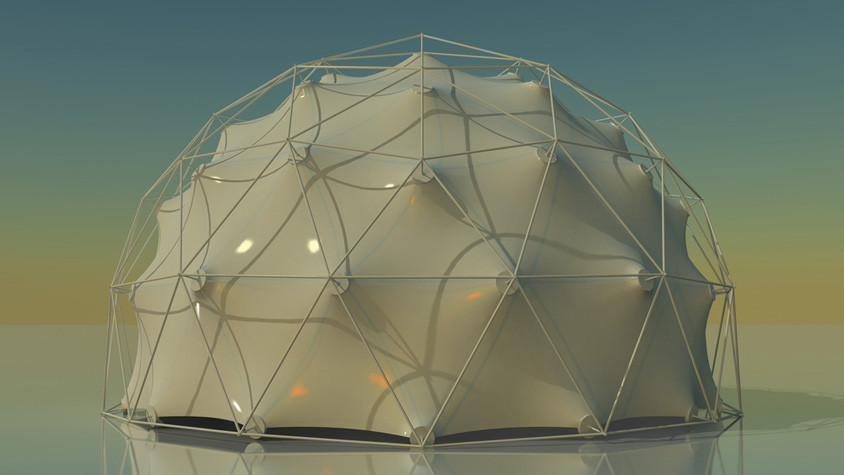

By combining modern 3D modeling with age-old weaving and knitting techniques, researchers at the University of Technology, Sydney (UTS) hope to create the portable shelter of the future.

Yet this structure aspires to be so much more than just a tent.

Waterproofed through coatings and additives embedded in the textile’s fibres, it will not only be able to withstand the elements, but its designers intend it to generate energy through solar power.

In a recent UTS article, UTS professor of Spatial Design and leader of the Architextile project, Benedict Anderson explained that the shelter is primarily aimed at “natural disaster relief, war zones and commercial applications.”

Architextile is currently being funded by an ATN-DAAD (Germanic Academic Exchange Service) Joint Research Co-operation Scheme grant and incorporates expertise from UTS, CSIRO and University of the Arts Berlin.

Each member of the project has a different area of focus in textile fabrication: fibres and yarns, weave structures and 3D architectural modelling.

UTS senior lecturer in Architecture and advanced modeling expert David Pigram has been tasked with the 3D modelling component.

“Textiles in architecture has been around for decades – we’ve seen flowing sails in building design for many years,” said Pigram. “However, recent advances mean the prospect of using textiles as the primary construction material is now within our reach.”

Ebba Waldhör, the textile specialist from the University of the Arts Berlin hopes to answer questions regarding what materials should be used to create a fabric that’s suitably breathable, insulating, waterproofed and can also support conducting threads. Yet it’s the specific premise of the project that interests Waldhör most.

“From a textile perspective this project is very intriguing,” she said. “The possibility to turn a two-dimensional textile into a three-dimensional shape in the manufacturing process opens up new ways of thinking about surface in relation to form. The limitations of conventional machines are a challenge however – most knitting machines, for example, are built to make garments, not houses.”

CSIRO materials scientist Dr Louis Kyratzis provides a key element to the project: he has already developed the flexible battery and solar panels that will be required for the eventual shelter to generate its own light and potentially even power devices.

Currently, the Architextile project aspires to have a prototype measuring three square metres ready by the end of this year, yet even its leader admits the old-fashioned tent is unlikely to become superseded anytime soon.

“Dropping a canvas tent is always going to be cheaper, but the way this project allows such seamless integration with technology opens up so many more applications. Not only do we have a structure that’s self-sustaining, constructing it from textiles offers a zero waste production process while maximising flexibility.”